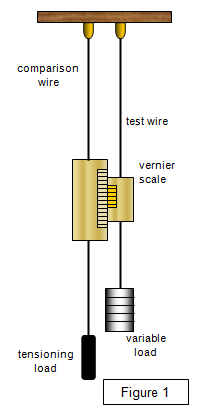

The Young modulus may be measured for a material in the form of a wire

using the apparatus shown in Figure 1.

Two identical wires are hung from a beam; a scale is

fixed to one wire and a mass hung on the end to remove kinks in it. This wire is used as a

reference standard. The other wire has a small load placed on it to straighten it and a vernier

scale which links with the scale on the reference wire.

The original length (L) of the test

wire is measured and its diameter is found for various points along its length and an average

diameter calculated. Hence its mean radius r can be found.

Loads are then placed gently

on the wire and the extension of the wire found for each one. They should not be dropped, as this

would subject the wire to a sudden shock. After each reading the load should be removed to check

that the wire returns to its original length, showing that its elastic limit has not been

exceeded.

A graph is plotted of stress against strain and from this the value of the Young

modulus may be found (this is the gradient of the line i.e. F/A divided by e/L).

The wires

should be long and thin to give as large an extension as possible for a given load while retaining its

elastic properties.

Two wires are used to eliminate errors due to changes of temperature and

sagging of the beam.